Key Elements of ISO 9001:2015 Quality Management System

-

By Sushmith

By Sushmith - Published on Sep 3 2024

Table of Contents

Elements of ISO 9001:2015 – An Overview

ISO 9001:2015 is an internationally recognized standard that outlines the requirements and helps organizations establish an effective Quality Management System (QMS). Designed to help businesses of all scales and all industries, this standard stands at the top, for playing a crucial role in improving customer satisfaction and ensuring consistent quality.

The ISO 9001 standard is built around a standardized framework that has the potential to enhance business processes that guarantee a service that meets customer and regulatory requirements. It provides detailed regulatory requirements for the products and services to follow. With this, businesses establish a systematic flow approach for managing quality, which in turn aids in achieving sustainability and driving innovation.

With the constant change in customer needs and demands, which is purely based on market and trends, it is very important to adapt to their needs to maintain sustainability for the growth. Taking the challenge to build a systematic, standardized culture offers multiple benefits like process efficacy, risk management, and compliance. The ISO 9001 standard not only helps maintain consistency/compliance but also creates a culture of quality, motivating the team to level up the organization's operations.

To get in depth about the elements of ISO 9001, let’s first learn the core principles of this standard.

Core Principles of ISO 9001:2015

Customer Focus

ISO 9001:2015 has a major focus on customer satisfaction. Businesses anticipate the demands to guarantee their goods and services continuously meet or surpass the demands of clients and customers. Companies can create lasting relationships and improve their market reach by putting the needs of their customers first.

Leadership

Any QMS must have strong leadership to be successful. The key elements of ISO 9001:2015 emphasizes how crucial it is for senior management to be dedicated to establishing precise goals, allocating the required funds, and cultivating a quality-conscious culture. In addition to making sure that every employee is inspired and given the authority to participate in the QMS, leaders are in charge of coordinating the organization's strategic orientation with its quality goals.

Engagement of People

Another such key principle is employee empowerment and involvement. Businesses succeed with QMS when the entire team operates effectively. Increased communication, a stronger dedication to quality, and a deeper understanding of procedures are the results of this involvement.

Process Approach

The core of a QMS is to be operated with a process-oriented methodology, according to ISO 9001:2015. Organizations improve consistency, efficiency, and effectiveness through linked processes. This QMS Approache aids in the identification of opportunities for enhancement and guarantees efficient resource allocation to attain planned results.

Improvement

Other fundamental elements of ISO 9001:2015 is continuous improvement. This Principle suggests organizations to do routine QMS evaluations, spot areas for improvement, and make adjustments that improve performance. Organizations can maintain their adaptability to market changes and trends if there is a commitment to consistent improvement.

Evidence-Based Decision Making

A QMS cannot function effectively unless decisions are made with knowledge. Decision-making should be done based on data, according to ISO 9001:2015. QMS processes increase performance by reducing risks and making smarter decisions that depend on reliable information.

Relationship Management

The effectiveness of the QMS depends on managing relationships with stakeholders, including partners, suppliers, and customers. In order to support their quality goals and ensure long-term success, businesses must cultivate solid, mutually beneficial relationships, as highlighted by ISO 9001:2015.

Key Elements of ISO 9001:2015

When it comes to implementing a QMS into any business operation, ISO 9001 stands at the top. But to effectively implement a QMS that aligns with the ISO 9001 standard, there are some key considerations to look after.

Context of the Organization

Understanding the context of an organization is the key to ensuring a QMS that aligns with strategic objectives. ISO 9001:2015 demands companies to take account of both internal and external elements that affect their capacity to provide quality. With this, QMS can be customized to meet the specific requirements as set by the company.

Leadership and Commitment

Effective application of the elements of ISO 9001:2015 and the standards is largely dependent on the management type. Team’s dedication to the QMS is determined by their proactive leadership, setting of precise quality goals, and the supply of essential resources. All organizational levels are guaranteed to maintain quality as a top priority thanks to this leadership.

Planning

Effective planning is essential for achieving the objectives of the QMS. ISO 9001:2015 demands organizations to set clear goals, identify potential risks, and then proactively allocate the resources. Proper planning helps identify potential challenges and guarantees the QMS remains effective over time.

Support

Support refers to the resources, communication, and other elements required for implementing QMS. It is important to train the team, which helps in carrying out the roles effectively. Clear communication and access to resources become the keys to a successful operation of QMS.

Operation

Operational processes and controls are the core of consistent quality delivery. ISO 9001 outlines the need for organizations to manage processes that meet the requirements of customers and regulatory bodies. As obvious, effective operations lead to improved efficiency and customer satisfaction.

Performance Evaluation

Evaluating the performance of the QMS helps maintain consistent improvement. ISO 9001 suggests organizations regularly assess their processes to measure outcomes and analyze data for areas of enhancement. This helps maintain QMS as effective and aligned with the set organization goals.

Improvement

With no improvement, there is no progress. Persistent improvement is essential for any organization to align for effective QMS. With ISO 9001:2015, organizations can take proactive steps to implement corrective actions and prevent future issues. This drives the organization toward higher levels of quality and operational excellence.

Conclusion

Implementing a QMS would be the best decision to be made by businesses of all sizes and industries. And using the ISO 9001 standard as one of the key tools for this is the best choice of action. In conclusion, ISO 9001:2015 is an all-rounder tool for organizations seeking to make adjustments to their QMS and prioritize customer needs at the top.

Organizations often face challenges with the implementation of ISO 9001:2015, but with proper team training and strategic resource allocation, organizations can enhance the quality of operations and the quality of the products or services. Understanding and clearly implementing the key elements of ISO 9001 offers a better standing within the corporation.

It certainly is not an easy process to achieve such a change, but it would for sure be worth it when these changes offer increasing satisfaction in customers and efficiency in operations. And to make this easier, Sprintzeal introduces you to the best certification training programs, designed and tailored to meet all the needs and expectations of professionals of all levels.

Enroll in Sprintzeal's ISO 9001:2015 certification training program to refine your quality management skills by learning the core principles and elements of ISO 9001 to take the organization's product/service quality to the top.

Subscribe to our Newsletters

Popular Programs

Trending Posts

Operation Manager Interview Questions and Answers

Last updated on Mar 13 2023

Explaining QMS Documentation Structure: Benefits and Best Practices

Last updated on Aug 28 2024

Lean Six Sigma on Resume for Rewarding Career Benefits

Last updated on Nov 20 2023

What Is Lean Management?

Last updated on Apr 20 2023

Quality Control Explained – Six Sigma

Last updated on Feb 21 2024

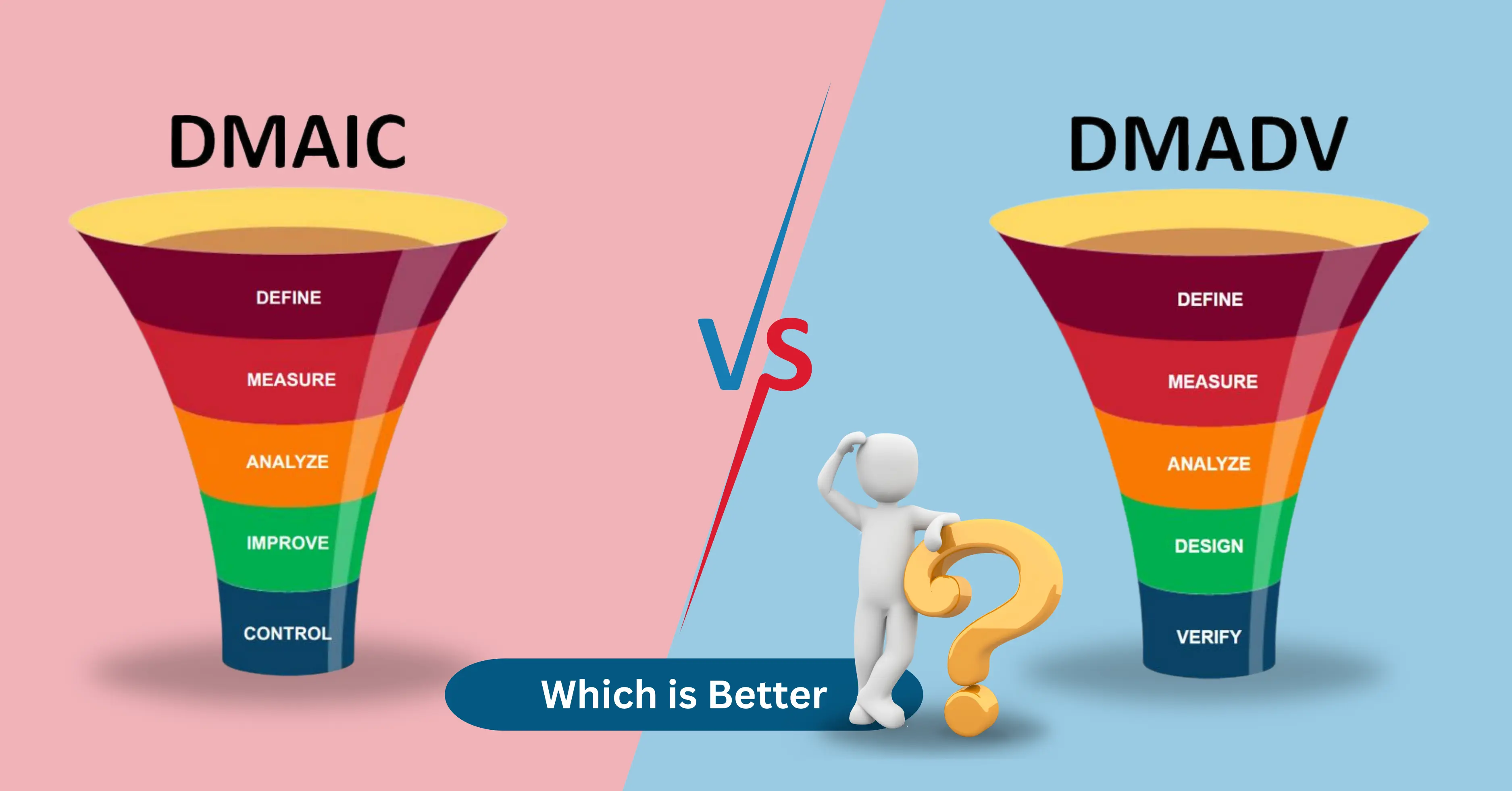

DMAIC vs. DMADV: Key Differences and Choosing the Right Six Sigma Methodology

Last updated on Nov 10 2023

Categories

- Agile Management 54

- AI and Machine Learning 42

- Big Data 53

- Business Management 51

- Cloud Computing 44

- Digital Marketing 56

- Information Security 8

- IT Hardware and Networking 17

- IT Security 103

- IT Service Management 29

- Leadership and Management 1

- Microsoft Program 2

- Other 43

- Programming Language 31

- Project Management 162

- Quality Management 75

- Risk Management 8

- Workplace Skill Building 2

Trending Now

Top Career benefits of Lean Six Sigma Green Belt

ArticleLean methodology, Six Sigma methodology and Lean Six Sigma Explained

ArticleSix Sigma Black Belt Certification – Value and Career Benefits in 2024

ArticlePareto Chart in Six Sigma - Explained

ArticleQuality Management Interview Questions 2024

ArticleSix Sigma Certification Guide - A Professional's Guide

ArticleSix Sigma Yellow Belt Certification - Six Sigma for Beginners

ArticleQuality Control Explained – Six Sigma

ArticleTotal Quality Management - A Complete Guide for Beginners

ArticleQuality Assurance in Six Sigma Explained

ArticleQuality Assurance vs Quality Control

ArticleSix Sigma Certification – Everything you Need to Know About Getting Certified

ArticleLean Six Sigma on Resume for Rewarding Career Benefits

ArticleQuality Manager Interview Questions and Answers for 2025

ebookService Delivery Manager Interview Questions and Answers (With Examples)

ArticleSix Sigma Interview Questions and Answers 2024

ArticleHow to become a Quality Analyst

ArticleA Supply Chain Management Guide to Mastering Logistics End to End

ArticleSenior Quality Manager Interview Questions and Answers 2024

ArticleTop 30 Quality Analyst Interview Questions and Answers 2025

ArticleFinancial Analyst Interview Questions and Answers 2024

ArticleRisk Manager Interview Questions and Answers 2024

ArticleCompliance Manager Interview Questions and Answers 2024

ArticleOperation Manager Interview Questions and Answers

Article5 Lean Continuous Improvement Principles to Supercharge Your Operations

ArticleHow to Become a Quality Manager - Career, Job Scope and Certifications

ArticleEssential Components of a Quality Management System

ArticleSix Sigma Certifications - Reasons Why you Should Get Them

ArticleTop Qualities of a Good Manager and a Leader

ArticleLearn about Statistical Process Control (SPC) and its top applications

ArticleCost of Poor Quality - A Detailed Guide

ArticleImplementing 5S Methodology for Better Work Efficiency

ArticleWhat Is Lean Management?

ArticleBest Six Sigma Books in 2024

ArticleLeadership vs Management - The Ultimate Guide

ArticleQuality Assurance Plan - Six Steps To Quality Assurance Plan

ArticleOperational Planning Creation, Key Elements and its Benefits

ArticleA Complete Guide to Product Life Cycle Stages 2025

ArticleSix Sigma tools for DMAIC Phases

ArticleWhat Is Lean Manufacturing?- An Overview

ArticleThe Lean Continuous Improvement Model: A Comprehensive Guide

ArticleDMAIC vs. DMADV: Key Differences and Choosing the Right Six Sigma Methodology

ArticleA Deep Dive into the Power of Lean Continuous Improvement Process

ArticleLean Continuous Improvement Methods for Business Excellence

ArticleIntroduction to Lean Manufacturing- Definitions, Framework, and More

ArticleUnderstanding the Key Principles of Lean Manufacturing

ArticleSecret to Unlock Organizational Excellence: Stages of Continuous Improvement

ArticleLean Continuous Improvement: A Detailed Guide to Mastering Organizational Quality

ArticleLean Waste Management: The Ultimate Guide 2023

ArticleA Deep Dive into Lean Continuous Improvement Tools

Article8 Wastes of Lean - Strategies for Identification and Elimination

ArticleThe Ultimate Guide to Lean Manufacturing

ArticleUnderstanding Lean Manufacturing's Pros and Cons

ArticleLean Waste Reduction Strategies: Boost Efficiency and Cut Costs

ArticleTop 10 Lean Manufacturing Tools for Optimal Productivity

ArticleBeyond the Basics: Benefits of Lean Continuous Improvement

ArticleWhat are Quality Standards? | A Guide to ISO Standards

Article7 Important Types of Quality Management System

ArticleA Comprehensive Guide to Quality Management Systems

ArticleISO 9001 Standard: Benefits and Certification

ArticleBenefits of QMS Certification for Your Business

ArticleStep-by-Step Implementation Guide to ISO 9001

ArticleThe Ultimate Guide to ISO 9001: Boosting Quality and Certification Success

ArticleQuality Management System – QSM Approaches and Methodologies

ArticleHow to Effectively Implement a Robust Quality Management System?

ArticleExplaining QMS Documentation Structure: Benefits and Best Practices

ArticleWho Needs ISO 9001 Certification and Why?

ArticleOvercoming Common Challenges in ISO 9001 Certification: Tips and Best Practices

ArticleBest Quality Management Tools

ArticleTotal Quality Management (TQM) vs. Six Sigma

ArticleQuality Manager Salary: What Freshers & Experts Earn in 2025

ArticleCertified Scrum Product Owner: Job Roles And Responsibilities

ArticleTips for Continuous Integration Testing: Streamlining QA

Article10 Quality Management Strategies Adopted by Top Managers

Article