Six Sigma Certifications - Reasons Why you Should Get Them

-

By Syed Irfan

By Syed Irfan - Published on Aug 18 2022

Six Sigma Certifications - Black Belt, Green Belt, Yellow Belt & Reasons to Get Certified

Table of Contents

1) Six Sigma History

2) What is Six Sigma Certification?

3) Different Six Sigma Certification Levels

4) Requirements for Six Sigma Certificate

5) Top reasons to get the Six Sigma certification

6) Benefits for Businesses to have Six Sigma Certified

7) About Six Sigma Certification

Lean Six Sigma methodologies can have a positive impact on your professional future.

The capability to include Six Sigma certification on your resume shows that you are committed to developing your analytical and business skills, and also improving the company in which you are employed.

Six Sigma belts have become highly sought after by professionals due to the value it adds to one’s portfolio. Even recruiters recognize its value and are on the lookout to spot candidates who possess Six Sigma belts.

While it is good to get Six Sigma belts for any professional, it is recommended to get the training for the same by a reputed authorized training partner to best learn the skills required to get the Six Sigma belts.

Six Sigma History

Six Sigma was created by Bill Smith in 1986. Then an engineer was able to improve the quality of the equipment of the company, which did not comply with the quality standards of the time. This laid the base for the plethora of Six Sigma belts that we have today.

He was influenced by the techniques that control the quality of products and techniques that were taught by Walter Shewhart, Ronald Fisher, and Edwards Deming, Walter Shewhart pioneered statistical quality control (SQC) and also developed the Plan Do Check Act (PDCA) model. This acted as the basis of the lean sigma method.

Edwards Deming is credited with the invention of the sampling methods employed by the Department of Census and the Bureau of Labor Statistics in the US.

Sir Ronald Aylmer Fish's work was the basis for various statistical methods that are used today. For instance, Student's T-distribution P-value, and F distribution, among others.

What is Six Sigma Certification?

Six Sigma is a collection of techniques and tools that companies use to improve their production processes reduce defects and ensure high the quality of their products.

This Lean Six Sigma certification can be used to validate professionals who are proficient in identifying errors, risks, or flaws in business processes and then removing them. Professionals seek out Lean Six Sigma certification to display their technical prowess.

The process of obtaining the Six Sigma Certification typically requires people to have a specific level of experience and demonstrate their competence. This is why it can take some time to get your Lean Six Sigma certification.

This certification will help you develop into a professional in improving processes and increase your credibility. This will help you understand the lean sigma process.

Various Six Sigma Certification Levels

Now that we've learned about a six-sigma certification, let's look at the various levels of certification. Professionals need to work their way up these Six Sigma certifications. They need to work their way up to the Six Sigma Master Black Belt which is the highest level among the Six Sigma belts.

Many six-sigma levels of certification include Black Belt, White Belt, Yellow Belt, Green Belt, and Master Black Belt. Getting the Six Sigma Master Black Belt culminates your journey through the Six Sigma belts.

Six Sigma White Belt

It is the most basic six-sigma certification that covers the most fundamental Six Sigma concepts.

White belts help with changes in the organization and work with local teams of problem-solving who assist in the implementation of projects. This is the first Six Sigma certification that you need to get.

Six Sigma Yellow Belt

At this stage, you have a solid understanding of the nuances that comprise Six Sigma, and how and how to use it. You'll assist teams in solving tasks. This will help you get familiar with the lean sigma process.

Six Sigma Green Belts

The Six Sigma green belt is a crucial stage in the certification process. At this point, you have a solid understanding of advanced analysis and can solve issues that impact the quality of your work.

Green belts are the ones who lead projects. This makes the Six Sigma green belt one of the most coveted Six Sigma belts. A lot of professionals aim to get the Six Sigma green belt so that they can lead projects.

The Six Sigma Green Belts also help black belts in the collection of data and analysis

Enroll in Lean six sigma green belt certification and get certified

Six Sigma Master Black Belt

The Six Sigma Black Belt is the top stage in Six Sigma’s achievement. At this point, you'll be able to shape your strategy, design important metrics, and serve as a consultant as well as coach green and black belts.

Getting the Six Sigma Black belt puts you on the top of the hierarchy of the Six Sigma Belts. This Six Sigma certification enables you to venture further in any direction within your domain.

Get certified with Lean six sigma black belt certification and level up in your career

The Six Sigma certification requirements as in accordance with IASSC requirements to be awarded the professional title IASSC certified Green Belt (IASSC-CGB(TM)) of the International Association for Six Sigma Certification It is required to take the IASSC accredited Lean Six Sigma Green Belt Test and gets an average score of 70.

There aren't any prerequisites to be able to pass this exam. IASSC Certification in Lean Six Sigma Green Belt Exam.

Top 5 Benefits of Getting Six Sigma Certification

Here are some good reasons for you to take the Six Sigma certification:

Help the Organization reduce risk and eliminate defects and errors

The process of acquiring a Six Sigma certification as well as Project Management Software like Celoxis, allows an individual to become vital for an organization's ability to find and fix mistakes?

In one instance, the Six Sigma process helped General Electric to save $350 million in 1998. Motorola to distribute their largest savers of $17 billion to 2005. The savings of GE grew to $1 billion in the following decade. Optimize the Business Process and Assist in Quality Improvement.

Upon the successful completion of the six-sigma green certification, you will be able to analyze the manufacturing and business processes of your company and take steps to increase the efficiency of these processes.

You will be capable of conducting a thorough analysis of current practices to know how they impact the quality of performance. In addition, certification will demonstrate that you can attain the kind of continuous quality improvement required by organizations.

This includes monitoring processes to ensure that there is no deviation from the norm and taking corrective actions to halt any project that is diverging from the plan.

Improve the Value across Industries

It is, without doubt, one of the top benefits of having the status of six sigma certification. Since it is an industry-neutral methodology, Six Sigma techniques are employed in the fields of aerospace, telecom finance, and banking as well as HR, IT marketing, and a myriad of other sectors.

Six Sigma certified professionals are proficient in a variety of methods that can be utilized to improve the processes of business, boost employee satisfaction, lower costs and boost revenues all of which contribute to an increase in profits regardless of industry.

Check for Compliance

Six Sigma demands very high-quality standards. Because of this, lots of suppliers, procurers, and oversight agencies apply Six Sigma standards in evaluating accounts or products. This is one of the top benefits of adopting the lean sigma process.

Professionals who are certified with Six Sigma Green Belt Certification help their businesses in ensuring that their contracts are profitable and in ensuring that they are compliant with international standards.

The rise to managerial positions

After you have completed your Six Sigma certification you will be able to comprehend the financial advantages that can be measured and quantified in the event of implementing the Six Sigma project.

You will develop the ability to assess risk and manage finances abilities that are highly sought-after by the top and middle-level managers for positions in senior management

Great Salary

Earning a six-sigma certification is not an easy accomplishment. The study is very demanding. The tests are not simple to take.

Furthermore, moving in belts from one level to another is a long-term commitment to work. So, it's not surprising that those with six-sigma certification are well-paid.

Professionals with the Six Sigma certification earn upwards of $110,000 which is among the top-paid professionals around the world. This is one of the main reasons professionals seek to get the Six Sigma belts.

The reality is that in India the country, a six-sigma certified professional can earn more than the amount of Rs. 20 Lakhs annually. For example, in France, a person who has been certified with six sigma is paid more than 62K EUR every year.

The reality is that in Singapore, an individual with a six-sigma certification can earn more than SG$53,000 or SG$220,000 per year, depending on experience and location. In the UK, professionals with a six-sigma certification can earn about PS60,000 per annum

A professional who has six sigma certification earns about EUR58K each year in Spain

In Canada professionals who have Six Sigma certification earn about C$78K annually.

Learn hands-on about Quality Management

The Six Sigma training course involves hands-on activities on industrial projects as well as the application of theoretical ideas to real-world situations.

Starting a Six Sigma course helps you to gain valuable experience before becoming a worker.

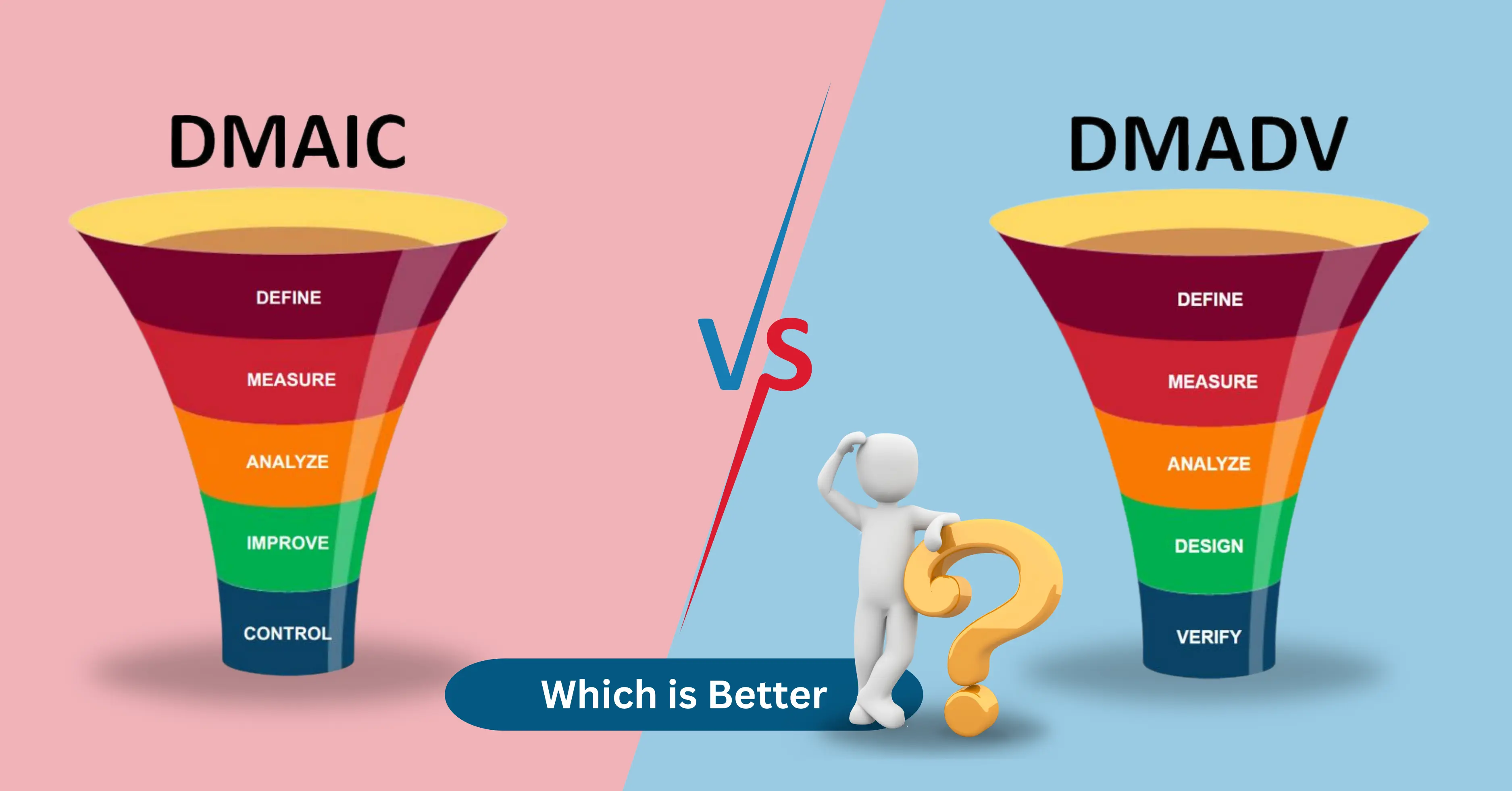

Learn in-depth about what Six Sigma phases define, evaluate, analyze, improve and manage (DMAIC) through DMAIC, the Lean Six Sigma Green Belt Certification.

Benefits for Organizations for Hiring Six Sigma Certified Professionals

Better Productivity

Space is needed to make new products; Allen DMAIC is a medically-owned method and lean tool. To increase the efficiency to increase the production rate

Arm boards to improve the rate of production. By using their new strategy, they were able to save an average of 45 seconds per arm board as well as increase the number of arm boards manufactured each hour, from 5.3 to just a little over 6.

Reduced Costs

Reducing defects reduces waste and consequently results in a lower cost of production and greater profits. Inability to produce a high-quality product is expensive.

Making a poor product or service could drastically reduce its value. This is what it means to “Cost of quality".

Increases confidence of your clients in your Business

The use of Six Sigma can help to reduce the complexity of processes and increase customer satisfaction.

For example, through the use of the Cross-functional Process Mapping (CFPM) method, Citibank was able to recognize the steps that are inefficient to improve their processes and correct the errors.

Which results in excellent results in the levels of satisfaction with their customers.

Gain Credibility and Stakeholder Trust

Customers and other stakeholders are confident in the company's employees who have the relevant credentials.

If a large proportion of your employees have the right qualifications, you can be sure that they are Six Sigma certified It signifies that their primary priority should be quality

A company that is focused on quality is competitive and builds trust with investors and partners.

Reduce turnover of employees and costs of training

The DMAIC method is also used in HR management, as described in an article published on the gate to research.

The article is an example of a multinational business that was losing millions of dollars because of the turnover of employees at 35 percent annually.

They wanted to cut the turnover rate to 25 percent. After the implementation of Six Sigma, they identified many contributing factors, chief of which was lack of career progression and inadequate salary.

To address the issue, they instituted new hiring processes and a new training program for new employees. The process yielded amazing results. Employee turnover decreased by 10%, resulting in savings totaling $1.1 million.

Popular Six Sigma Certifications:

Six Sigma Green Belt Certification

Six Sigma Black Belt Certification

Six Sigma Yellow Belt Certification

Lean six sigma green belt certification

Lean six sigma black belt certification

As you will discover, the importance of getting Six Sigma certification cannot be overemphasized. Six Sigma certifications have been shown to have a lasting positive impact on careers.

To individuals, remaining competent and employable in a marketplace with declining employment prospects is essential. Employers you can rest on the assurance the production line is managed by experts whose main concern is quality.

This is the reason obtaining an official Six Sigma certification must be the next step for you and we've got it all covered for you with Sprintzeal Lean Six Sigma Masters.

This course will be taught through Green or Black Belt certified professionals with more than ten years knowledge within Quality Management as well as will assist you to become an expert in the field. Sprintzeal’s Six Sigma Green Belt certification training will give the knowledge required to pass the test on the first try.

Take a look at our Certified Lean Six Sigma Green Belt Online Training classes in the classrooms of the best cities. Start your journey through the Six Sigma Belts today!

To get full details about six sigma training, chat with our course expert

Suggested Read – Six Sigma Certification Guide 2024

Subscribe to our Newsletters

Popular Programs

Trending Posts

Benefits of QMS Certification for Your Business

Last updated on Jul 1 2024

DMAIC vs. DMADV: Key Differences and Choosing the Right Six Sigma Methodology

Last updated on Nov 10 2023

Six Sigma Certification – Everything you Need to Know About Getting Certified

Last updated on Nov 8 2023

Lean Continuous Improvement Methods for Business Excellence

Last updated on Nov 21 2023

Six Sigma tools for DMAIC Phases

Last updated on Nov 8 2024

Financial Analyst Interview Questions and Answers 2024

Last updated on Jan 13 2023

Categories

- Agile Management 54

- AI and Machine Learning 42

- Big Data 53

- Business Management 51

- Cloud Computing 44

- Digital Marketing 56

- Information Security 8

- IT Hardware and Networking 17

- IT Security 103

- IT Service Management 29

- Leadership and Management 1

- Microsoft Program 2

- Other 43

- Programming Language 31

- Project Management 162

- Quality Management 75

- Risk Management 8

- Workplace Skill Building 2

Trending Now

Top Career benefits of Lean Six Sigma Green Belt

ArticleLean methodology, Six Sigma methodology and Lean Six Sigma Explained

ArticleSix Sigma Black Belt Certification – Value and Career Benefits in 2024

ArticlePareto Chart in Six Sigma - Explained

ArticleQuality Management Interview Questions 2024

ArticleSix Sigma Certification Guide - A Professional's Guide

ArticleSix Sigma Yellow Belt Certification - Six Sigma for Beginners

ArticleQuality Control Explained – Six Sigma

ArticleTotal Quality Management - A Complete Guide for Beginners

ArticleQuality Assurance in Six Sigma Explained

ArticleQuality Assurance vs Quality Control

ArticleSix Sigma Certification – Everything you Need to Know About Getting Certified

ArticleLean Six Sigma on Resume for Rewarding Career Benefits

ArticleQuality Manager Interview Questions and Answers for 2025

ebookService Delivery Manager Interview Questions and Answers (With Examples)

ArticleSix Sigma Interview Questions and Answers 2024

ArticleHow to become a Quality Analyst

ArticleA Supply Chain Management Guide to Mastering Logistics End to End

ArticleSenior Quality Manager Interview Questions and Answers 2024

ArticleTop 30 Quality Analyst Interview Questions and Answers 2025

ArticleFinancial Analyst Interview Questions and Answers 2024

ArticleRisk Manager Interview Questions and Answers 2024

ArticleCompliance Manager Interview Questions and Answers 2024

ArticleOperation Manager Interview Questions and Answers

Article5 Lean Continuous Improvement Principles to Supercharge Your Operations

ArticleHow to Become a Quality Manager - Career, Job Scope and Certifications

ArticleEssential Components of a Quality Management System

ArticleTop Qualities of a Good Manager and a Leader

ArticleLearn about Statistical Process Control (SPC) and its top applications

ArticleCost of Poor Quality - A Detailed Guide

ArticleImplementing 5S Methodology for Better Work Efficiency

ArticleWhat Is Lean Management?

ArticleBest Six Sigma Books in 2024

ArticleLeadership vs Management - The Ultimate Guide

ArticleQuality Assurance Plan - Six Steps To Quality Assurance Plan

ArticleOperational Planning Creation, Key Elements and its Benefits

ArticleA Complete Guide to Product Life Cycle Stages 2025

ArticleSix Sigma tools for DMAIC Phases

ArticleWhat Is Lean Manufacturing?- An Overview

ArticleThe Lean Continuous Improvement Model: A Comprehensive Guide

ArticleDMAIC vs. DMADV: Key Differences and Choosing the Right Six Sigma Methodology

ArticleA Deep Dive into the Power of Lean Continuous Improvement Process

ArticleLean Continuous Improvement Methods for Business Excellence

ArticleIntroduction to Lean Manufacturing- Definitions, Framework, and More

ArticleUnderstanding the Key Principles of Lean Manufacturing

ArticleSecret to Unlock Organizational Excellence: Stages of Continuous Improvement

ArticleLean Continuous Improvement: A Detailed Guide to Mastering Organizational Quality

ArticleLean Waste Management: The Ultimate Guide 2023

ArticleA Deep Dive into Lean Continuous Improvement Tools

Article8 Wastes of Lean - Strategies for Identification and Elimination

ArticleThe Ultimate Guide to Lean Manufacturing

ArticleUnderstanding Lean Manufacturing's Pros and Cons

ArticleLean Waste Reduction Strategies: Boost Efficiency and Cut Costs

ArticleTop 10 Lean Manufacturing Tools for Optimal Productivity

ArticleBeyond the Basics: Benefits of Lean Continuous Improvement

ArticleWhat are Quality Standards? | A Guide to ISO Standards

Article7 Important Types of Quality Management System

ArticleA Comprehensive Guide to Quality Management Systems

ArticleISO 9001 Standard: Benefits and Certification

ArticleBenefits of QMS Certification for Your Business

ArticleStep-by-Step Implementation Guide to ISO 9001

ArticleThe Ultimate Guide to ISO 9001: Boosting Quality and Certification Success

ArticleQuality Management System – QSM Approaches and Methodologies

ArticleHow to Effectively Implement a Robust Quality Management System?

ArticleExplaining QMS Documentation Structure: Benefits and Best Practices

ArticleWho Needs ISO 9001 Certification and Why?

ArticleKey Elements of ISO 9001:2015 Quality Management System

ArticleOvercoming Common Challenges in ISO 9001 Certification: Tips and Best Practices

ArticleBest Quality Management Tools

ArticleTotal Quality Management (TQM) vs. Six Sigma

ArticleQuality Manager Salary: What Freshers & Experts Earn in 2025

ArticleCertified Scrum Product Owner: Job Roles And Responsibilities

ArticleTips for Continuous Integration Testing: Streamlining QA

Article10 Quality Management Strategies Adopted by Top Managers

Article