Total Quality Management (TQM) vs. Six Sigma

-

By Afra Noorain

By Afra Noorain - Published on Oct 10 2024

Introduction

This blog explores the key principles and methods behind TQM and Six Sigma, highlighting the contrast between employee-driven improvement and data-focused precision. Whether your goal is continuous progress or near-perfect outcomes, this guide will help you choose the right strategy for boosting your business operations.

Table of Contents

- Origins and Evolution of TQM and Six Sigma

- The Foundations: Understanding TQM and Six Sigma

- Methodologies and Tools

- Focus: Employee Involvement vs. Data-Driven Precision

- Metrics and Implementation

- Flexibility vs. Structure

- Pros and Cons of Each Approach

- Conclusion: Choosing Between TQM and Six Sigma

Origins and Evolution of TQM and Six Sigma

In the modern world of business competition, upholding superior quality standards is essential for sustained success. Companies commonly turn to Total Quality Management (TQM) and Six Sigma as methodologies to achieve this objective. Although both methods target increased efficiency, defect reduction, and improved quality, they vary in methods, backgrounds, and scopes. In this blog, we will explore the distinctive features of each methodology, outline their variances, and assist you in identifying the most suitable approach for your business.

The Foundations: Understanding TQM and Six Sigma

Learn how TQM and Six Sigma originated and evolved to address quality management in different ways:

Total Quality Management (TQM)is an older concept that originated in the mid-20th century, largely influenced by quality pioneers like W. Edwards Deming and Joseph Juran. TQM emphasizes a holistic, company-wide commitment to continuous improvement and customer satisfaction. It seeks to embed quality as an organizational culture rather than as a specific project or initiative.

Six Sigma surfaced in the 1980s at Motorola as a data-driven technique to decrease defects and enhance processes. It focuses on reducing variation through statistical analysis and quantifiable metrics, gaining prominence when General Electric adopted it. Six Sigma strives for near-perfection by limiting defects to 3.4 per million opportunities.

Methodologies and Tools

TQM uses tools like the PDCA (Plan, Do, Check, Act) cycle to promote continuous improvement, encouraging employee participation at every level. It focuses on improving processes through collaborative efforts, ensuring customer satisfaction by fostering a quality-conscious culture.

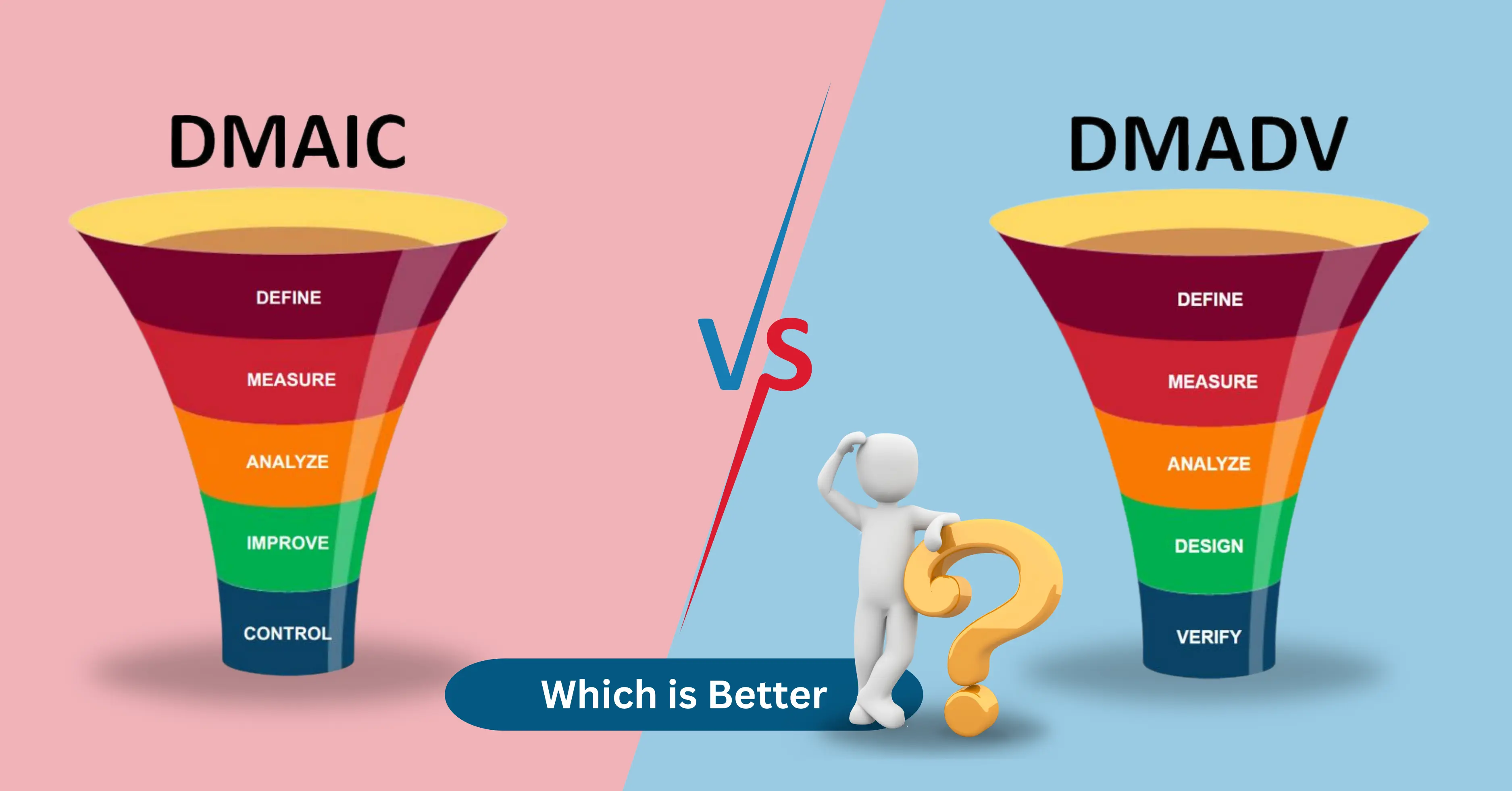

Six Sigma, however, adopts a more structured approach. Its DMAIC (Define, Measure, Analyze, Improve, Control), framework offers a clear path for problem-solving, integrating advanced statistical tools like control charts, process mapping, and regression analysis to pinpoint and eradicate the root causes of defects.

While TQM relies on various quality management tools like Pareto charts, fishbone diagrams, and flowcharts, Six Sigma emphasizes data-centric tools that provide measurable outcomes. The difference in tools reflects the broader, employee-driven approach of TQM versus the more specialized, statistical nature of Six Sigma.

Focus: Employee Involvement vs. Data-Driven Precision

One key distinction between the two methodologies is their primary focus.

- TQM prioritizes people, encouraging employee participation at all organizational levels. Whether it’s frontline workers or top management, TQM encourages everyone to take part in quality improvement initiatives. This participatory approach builds a quality-oriented culture, empowering employees to take responsibility for improvements and customer satisfaction.

-Six Sigma is data-centric. The methodology focuses on measuring and analyzing data to achieve process improvements. In Six Sigma, trained professionals, often designated as Green Belts or Black Belts, lead improvement projects. Their expertise in statistical analysis ensures precise identification and elimination of inefficiencies or defects.

Metrics and Implementation

The metrics used by Six Sigma are particular. Six Sigma practitioners measure success by metrics like Defects Per Million Opportunities (DPMO) and Sigma Levels, which offer a precise measure of process efficiency. Achieving Six Sigma means only 3.4 defects per million, a nearly flawless process. Its project-based implementation often leads to significant gains in quality and cost savings, though it requires a significant investment in training and resources.

In contrast, TQM metrics are broader and more flexible, including customer satisfaction scores and overall defect rates. TQM aims to improve quality continuously, often without the stringent statistical measures of Six Sigma. TQM’s holistic approach is less formalized, allowing companies to adapt quality initiatives according to their needs and industry standards.

Flexibility vs. Structure

Another major difference is in how the two methodologies are applied across industries.

- TQM is often seen as more flexible. Its focus on employee involvement and customer satisfaction allows it to be applied across diverse industries, from manufacturing to services. It promotes a culture of quality that becomes ingrained in the organization’s DNA, which means it can be tailored to suit various operational needs.

- Six Sigma, however, tends to be more rigorous and structured. It’s best suited for organizations where processes can be quantitatively analyzed and optimized through statistical means. For companies that require high precision and minimal variation—such as in manufacturing or healthcare, Six Sigma’s structured approach delivers clear, measurable results.

Pros and Cons of Each Approach

Both methodologies offer unique advantages and challenges depending on organizational objectives and resources.

Pros of TQM:

- Fosters a quality-focused culture with broad employee involvement.

- Easily adaptable to various industries and departments.

- Emphasizes long-term customer satisfaction and continuous improvement.

Cons of TQM:

- Can lack structure, making it harder to quantify improvement.

- Requires company-wide commitment, which may be difficult to achieve in larger organizations.

Pros of Six Sigma:

- Offers precise, data-driven solutions for process improvement.

- Produces measurable results in terms of defect reduction and cost savings.

- Provides a structured approach with clear roles (e.g., Green and Black Belts).

Cons of Six Sigma:

- May require significant resources and training.

- Implementation can be costly and time-consuming, especially for smaller organizations.

- Its focus on metrics can sometimes overlook broader customer satisfaction.

Conclusion: Choosing Between TQM and Six Sigma

Both TQM and Six Sigma offer powerful frameworks for improving quality, but the best choice depends on your organization’s unique needs. If your goal is to foster a culture of quality that involves employees at all levels, TQM might be the better fit. It emphasizes continuous improvement and flexibility, making it suitable for diverse industries.

On the other hand, if your business requires quantifiable results and a data-driven approach to process improvement, Six Sigma may provide the structured methodology needed to reduce defects and improve efficiency.

Ultimately, organizations may even choose to combine elements of both methodologies, creating a hybrid approach that draws on the strengths of each. Head over to Sprintzeal and explore our comprehensive Six Sigma certification courses, tailored to equip you with the skills necessary for operational excellence. Contact us today to find the course that fits your needs and elevate your business's quality management strategy.

Subscribe to our Newsletters

Popular Programs

Trending Posts

DMAIC vs. DMADV: Key Differences and Choosing the Right Six Sigma Methodology

Last updated on Nov 10 2023

Leadership vs Management - The Ultimate Guide

Last updated on May 9 2024

8 Wastes of Lean - Strategies for Identification and Elimination

Last updated on Dec 27 2023

Explaining QMS Documentation Structure: Benefits and Best Practices

Last updated on Aug 28 2024

Quality Control Explained – Six Sigma

Last updated on Feb 21 2024

Quality Assurance Plan - Six Steps To Quality Assurance Plan

Last updated on Mar 14 2025

Categories

- Agile Management 54

- AI and Machine Learning 42

- Big Data 53

- Business Management 51

- Cloud Computing 44

- Digital Marketing 56

- Information Security 8

- IT Hardware and Networking 17

- IT Security 103

- IT Service Management 29

- Leadership and Management 1

- Microsoft Program 2

- Other 43

- Programming Language 31

- Project Management 162

- Quality Management 75

- Risk Management 8

- Workplace Skill Building 2

Trending Now

Top Career benefits of Lean Six Sigma Green Belt

ArticleLean methodology, Six Sigma methodology and Lean Six Sigma Explained

ArticleSix Sigma Black Belt Certification – Value and Career Benefits in 2024

ArticlePareto Chart in Six Sigma - Explained

ArticleQuality Management Interview Questions 2024

ArticleSix Sigma Certification Guide - A Professional's Guide

ArticleSix Sigma Yellow Belt Certification - Six Sigma for Beginners

ArticleQuality Control Explained – Six Sigma

ArticleTotal Quality Management - A Complete Guide for Beginners

ArticleQuality Assurance in Six Sigma Explained

ArticleQuality Assurance vs Quality Control

ArticleSix Sigma Certification – Everything you Need to Know About Getting Certified

ArticleLean Six Sigma on Resume for Rewarding Career Benefits

ArticleQuality Manager Interview Questions and Answers for 2025

ebookService Delivery Manager Interview Questions and Answers (With Examples)

ArticleSix Sigma Interview Questions and Answers 2024

ArticleHow to become a Quality Analyst

ArticleA Supply Chain Management Guide to Mastering Logistics End to End

ArticleSenior Quality Manager Interview Questions and Answers 2024

ArticleTop 30 Quality Analyst Interview Questions and Answers 2025

ArticleFinancial Analyst Interview Questions and Answers 2024

ArticleRisk Manager Interview Questions and Answers 2024

ArticleCompliance Manager Interview Questions and Answers 2024

ArticleOperation Manager Interview Questions and Answers

Article5 Lean Continuous Improvement Principles to Supercharge Your Operations

ArticleHow to Become a Quality Manager - Career, Job Scope and Certifications

ArticleEssential Components of a Quality Management System

ArticleSix Sigma Certifications - Reasons Why you Should Get Them

ArticleTop Qualities of a Good Manager and a Leader

ArticleLearn about Statistical Process Control (SPC) and its top applications

ArticleCost of Poor Quality - A Detailed Guide

ArticleImplementing 5S Methodology for Better Work Efficiency

ArticleWhat Is Lean Management?

ArticleBest Six Sigma Books in 2024

ArticleLeadership vs Management - The Ultimate Guide

ArticleQuality Assurance Plan - Six Steps To Quality Assurance Plan

ArticleOperational Planning Creation, Key Elements and its Benefits

ArticleA Complete Guide to Product Life Cycle Stages 2025

ArticleSix Sigma tools for DMAIC Phases

ArticleWhat Is Lean Manufacturing?- An Overview

ArticleThe Lean Continuous Improvement Model: A Comprehensive Guide

ArticleDMAIC vs. DMADV: Key Differences and Choosing the Right Six Sigma Methodology

ArticleA Deep Dive into the Power of Lean Continuous Improvement Process

ArticleLean Continuous Improvement Methods for Business Excellence

ArticleIntroduction to Lean Manufacturing- Definitions, Framework, and More

ArticleUnderstanding the Key Principles of Lean Manufacturing

ArticleSecret to Unlock Organizational Excellence: Stages of Continuous Improvement

ArticleLean Continuous Improvement: A Detailed Guide to Mastering Organizational Quality

ArticleLean Waste Management: The Ultimate Guide 2023

ArticleA Deep Dive into Lean Continuous Improvement Tools

Article8 Wastes of Lean - Strategies for Identification and Elimination

ArticleThe Ultimate Guide to Lean Manufacturing

ArticleUnderstanding Lean Manufacturing's Pros and Cons

ArticleLean Waste Reduction Strategies: Boost Efficiency and Cut Costs

ArticleTop 10 Lean Manufacturing Tools for Optimal Productivity

ArticleBeyond the Basics: Benefits of Lean Continuous Improvement

ArticleWhat are Quality Standards? | A Guide to ISO Standards

Article7 Important Types of Quality Management System

ArticleA Comprehensive Guide to Quality Management Systems

ArticleISO 9001 Standard: Benefits and Certification

ArticleBenefits of QMS Certification for Your Business

ArticleStep-by-Step Implementation Guide to ISO 9001

ArticleThe Ultimate Guide to ISO 9001: Boosting Quality and Certification Success

ArticleQuality Management System – QSM Approaches and Methodologies

ArticleHow to Effectively Implement a Robust Quality Management System?

ArticleExplaining QMS Documentation Structure: Benefits and Best Practices

ArticleWho Needs ISO 9001 Certification and Why?

ArticleKey Elements of ISO 9001:2015 Quality Management System

ArticleOvercoming Common Challenges in ISO 9001 Certification: Tips and Best Practices

ArticleBest Quality Management Tools

ArticleQuality Manager Salary: What Freshers & Experts Earn in 2025

ArticleCertified Scrum Product Owner: Job Roles And Responsibilities

ArticleTips for Continuous Integration Testing: Streamlining QA

Article10 Quality Management Strategies Adopted by Top Managers

Article