What Is Lean Manufacturing?- An Overview

-

By Niharika Chaurasia

By Niharika Chaurasia - Published on Nov 6 2023

Table of Contents

What Is Lean Manufacturing?

Step into the realm of Lean Manufacturing, a world of peak efficiency and minimal waste. In today's fast-paced and fiercely competitive business landscape, grasping the essentials of Lean Manufacturing isn't a choice but a must. Whether you're an experienced pro or just starting your Quality Management journey, this in-depth guide equips you with the knowledge to excel in modern industries.

Did you know that, on average, companies can slash operational expenses by 20-50% through Lean Manufacturing practices? This approach has transformed countless companies and industries, making it a hot topic in today's business landscape. In today's ever-changing global economy, the concept of lean thinking has gained even more importance. This thorough guide will lead you on a tour of the world of lean manufacturing. We'll investigate its historical beginnings; understand how it functions, and why it holds significance and how it can benefit us.

Whether you are an experienced expert or just entering the workforce, this blog will provide you with the information you need to tap into the potential of lean manufacturing in your specific situation.

When and Who Invented It?

Lean manufacturing has an interesting backstory that goes way back to the early 1900s. Knowing where it came from and the people who first came up with these ideas is super important to understanding why it's such a big deal today.

Lean manufacturing, which is also called the Toyota Production System (TPS), started in Japan. It was a way for Japan to deal with its economic challenges after World War II. The founders of lean manufacturing recognized the need to rebuild the Japanese economy efficiently. Here's a brief overview of its historical evolution:

The Birth of Lean

Lean Manufacturing's earliest origins are often associated with the ideas of American engineers and quality gurus like Frederick W. Taylor and Frank Gilbreth. They focused on improving efficiency and reducing waste in manufacturing processes. Taylor's scientific management and Gilbreth's time-motion studies laid the groundwork for Lean principles.

Post-War Japan

After World War II, the United States shared its manufacturing expertise with Japan to help rebuild the country's economy. Japanese engineers and industrial leaders, most notably Taiichi Ohno and Shigeo Shingo at Toyota, absorbed these principles and added their unique twist.

Key Figures and Pioneers in Lean Thinking

Taiichi Ohno

Often regarded as the father of the Toyota Production System (TPS), Taiichi Ohno revolutionized manufacturing. He introduced concepts like "Just-in-Time" and "Kanban," which became foundational to Lean Manufacturing. Ohno emphasized eliminating waste, continuously improving processes, and empowering workers.

Shigeo Shingo

A close collaborator of Taiichi Ohno, contributed to the TPS by developing techniques like Poka-Yoke (error-proofing) and Single-Minute Exchange of Die (SMED). His work focused on reducing defects and minimizing setup times in manufacturing.

Edwards Deming

Although not a Japanese figure, W. Edwards Deming made a significant impact on the development of Lean Thinking. He emphasized statistical quality control and the importance of continuous improvement, laying the groundwork for Lean's focus on data-driven decision-making.

The Lean principles developed by these pioneers continue to be relevant and influential in various industries today.

How Does It Work?

Lean Manufacturing relies on fundamental principles and essential methods that collaborate to simplify processes and remove unnecessary steps. These principles and techniques are the heart of how Lean Manufacturing operates.

The lean manufacturing is based on the principle:

Identifying Value

In Lean Manufacturing, the initial step involves understanding what matters most to the customer. This concept of "value" refers to what the customer is ready to spend money on. It's important because everything in Lean revolves around delivering value to the customer. To do this, you need to understand the customer's needs and preferences.

Example: If you're making bicycles, the customer values a sturdy frame, good brakes, and comfortable seats.

Mapping the Value Stream

After understanding what the customer values, the next step is to map out the entire process that goes into creating a product or providing a service. This helps identify every step, from raw materials to the finished product, and highlights any wasteful activities.

Example: In the bicycle manufacturing process, mapping might reveal that there's too much time spent waiting for parts to arrive or that there's a lot of back-and-forth movement between workstations.

Creating Flow

Once you've mapped the value stream, the goal is to make everything flow smoothly. You want to minimize interruptions, delays, and disruptions in the process. This step is about making sure work moves efficiently from one step to the next.

Example: In the bicycle factory, you would arrange workstations so that the frame, brakes, and seats move from one station to the next without waiting.

Establishing Pull Systems

Lean Manufacturing uses a "pull" system. This means you only produce or provide something when there's a demand for it. It's like going to a restaurant – they make your food when you order it. This reduces excess inventory and waste. Example: In our bicycle factory, parts are only ordered or assembled when there's a customer order, preventing the accumulation of unused parts.

Seeking Perfection

Lean Manufacturing is all about getting better all the time. It's like a never-ending journey to make things work more efficiently and smoothly. The main goal is to be the best you can be, even if you can't reach perfection.

For instance, the bicycle factory keeps discovering fresh ways to build bicycles more quickly and with even better quality, every year.

Lean Manufacturing Techniques

The techniques which make Lean manufacturing a first choice for the industries are:

Just-in-Time (JIT) Production

JIT means making products just in time to meet customer demand. This reduces the need for large inventories and prevents overproduction, saving money and reducing waste.

Example: Car manufacturers only order the specific number of parts they need to build cars, reducing the storage space and costs associated with unused parts.

5S Methodology

The 5S methodology focuses on organizing the workplace for efficiency and effectiveness. It consists of five steps: Sort, Set in order, Shine, Standardize, and Sustain. This helps maintain a clean and organized workspace, reducing errors and waste.

Example: In a hospital, 5S methodology is used to organize medical supplies, making it easy for staff to find what they need quickly and reducing the chances of medical errors.

Total Productive Maintenance (TPM)

TPM is all about keeping machines and equipment in excellent working condition. Preventing breakdowns and maintaining equipment improves productivity and reduces downtime.

Example: In a bakery, regular machine maintenance ensures ovens and mixers work smoothly, preventing delays in making and baking bread.

Kaizen Events

Kaizen means "continuous improvement" in Japanese. Kaizen events are focused improvement activities that involve employees from all levels. They work together to solve specific problems and improve processes.

Example: In an office, a Kaizen event might involve a team working to streamline the process of handling customer inquiries, resulting in faster response times and improved customer satisfaction.

These core principles and key techniques of Lean Manufacturing work together to create more efficient, cost-effective, and customer-centric processes in various industries. The goal is to provide value to customers while minimizing waste and continually striving for improvement.

Why Is It Important and How Can It Help?

Lean manufacturing is not just a trendy term; it's a highly effective method that can change the way businesses work in different fields. In this section, we'll discuss why lean manufacturing is crucial and how it can be beneficial.

Lean Manufacturing is like a versatile toolkit that can be applied in nearly every industry. Here's why it holds such significance:

Cost Reduction

Lean helps companies cut down on wasteful practices, which means they spend less money on unnecessary things. This is crucial in manufacturing, healthcare, and even services like banking.

Improved Quality

By focusing on quality at every step, Lean helps produce better products. Customers in industries like automotive and electronics benefit from this.

Faster Production

Lean streamlines processes, making production faster. This is a game-changer in industries like food, where freshness is key.

Enhanced Employee Satisfaction

Lean involves everyone, making work more engaging and rewarding. Employees in industries like retail and education see improvements in their daily tasks.

Adaptability

Lean is flexible and can adapt to different industries and situations, making it valuable in sectors from aerospace to software development.

Implementing Lean Manufacturing principles comes with a host of advantages:

- Reduced Waste: Lean helps identify and eliminate waste, which can be anything from overproduction to waiting times. This reduces costs and saves resources.

- Increased Productivity: Streamlining processes and reducing downtime means that workers can be more productive.

- Higher Quality Products: A focus on quality ensures fewer defects, which, in turn, satisfies customers and reduces rework.

- Improved Lead Times: Lean helps companies respond to customer demands more quickly, reducing lead times and increasing customer satisfaction.

- Enhanced Employee Engagement: Employees feel more involved and valued, leading to a happier and more motivated workforce.

Conclusion

In conclusion, Lean Manufacturing is a powerful methodology that has revolutionized industries. Its principles, which focus on eliminating waste and promoting continuous improvement, are key to achieving operational excellence.

Lean Manufacturing isn't limited to one specific sector. Its principles are versatile and can be applied across various industries, including manufacturing, healthcare, and services. The advantages are clear, resulting in improved efficiency, reduced waste, and enhanced quality.

If you're looking to deepen your understanding of Lean Manufacturing or want to become a Lean expert, consider exploring training programs. One such option is offered by Sprintzeal. Their Lean Management courses are designed to equip you with the knowledge and skills needed to implement Lean principles effectively in your organization.

Take the next step towards mastering Lean Manufacturing by enrolling in one of Sprintzeal's courses. Lean experts are in high demand, and by investing in your education, you'll position yourself for a successful and rewarding career.

FAQ

What is meant by lean manufacturing?

Lean manufacturing is a production philosophy and methodology aimed at minimizing waste, improving efficiency, and delivering value to customers while reducing costs.

What is 5S in lean manufacturing?

5S in lean manufacturing is a workplace organization method that stands for Sort, Set in order, Shine, Standardize, and Sustain. It's used to create a clean, organized, and efficient work environment.

What are 3 examples of lean manufacturing?

Three examples of lean manufacturing techniques are Just-in-Time (JIT) production, Kanban systems for inventory control, and Value Stream Mapping (VSM) to identify and eliminate process inefficiencies.

What is lean manufacturing and why is it important?

Lean manufacturing is important because it helps companies enhance productivity, reduce waste, improve quality, and respond more effectively to customer demand, ultimately leading to cost savings and increased competitiveness in the market.

Subscribe to our Newsletters

Popular Programs

Trending Posts

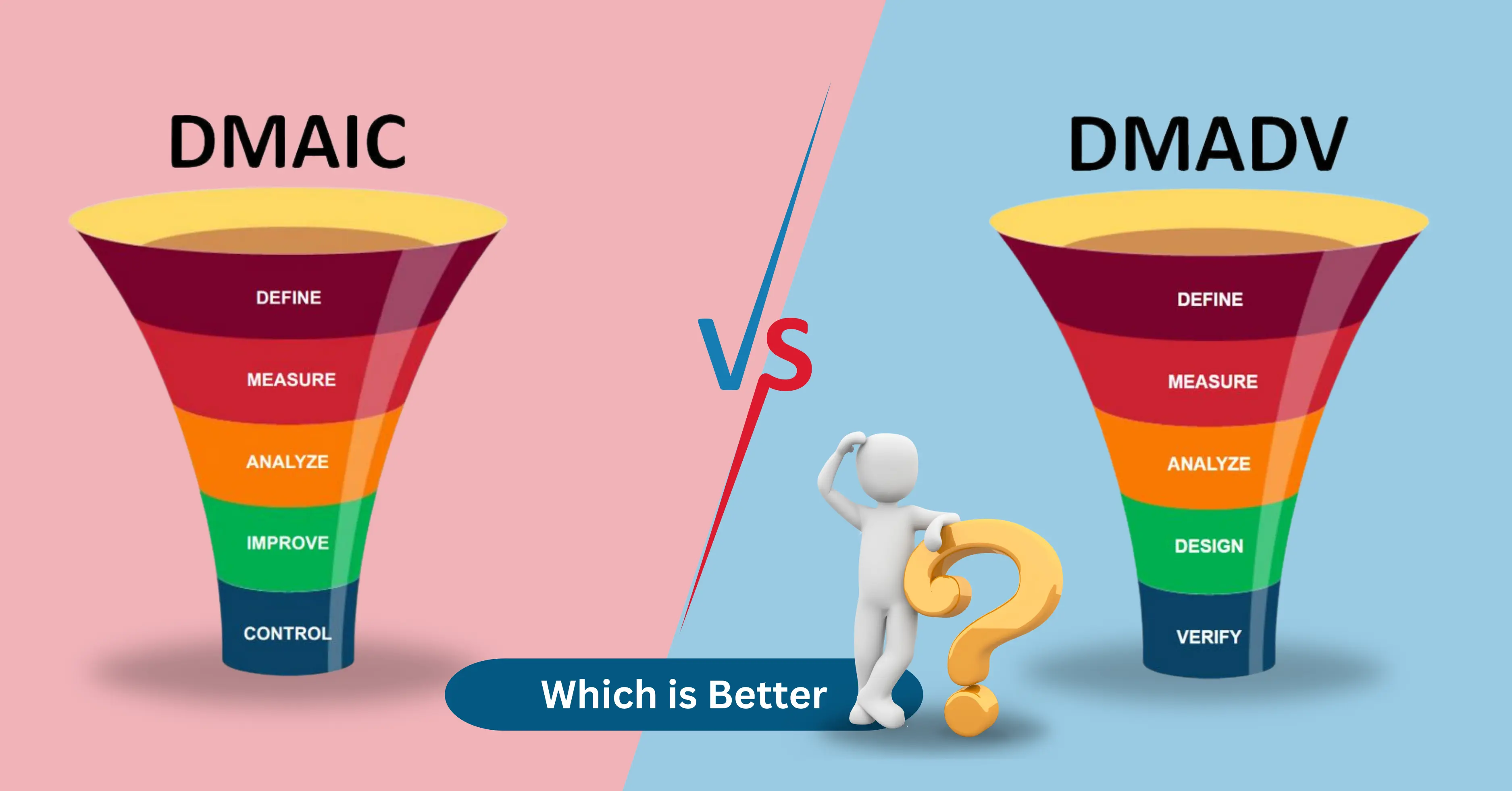

DMAIC vs. DMADV: Key Differences and Choosing the Right Six Sigma Methodology

Last updated on Nov 10 2023

Six Sigma Certification – Everything you Need to Know About Getting Certified

Last updated on Nov 8 2023

Quality Manager Salary: What Freshers & Experts Earn in 2025

Last updated on Feb 3 2025

The Lean Continuous Improvement Model: A Comprehensive Guide

Last updated on Nov 7 2023

Certified Scrum Product Owner: Job Roles And Responsibilities

Last updated on Feb 17 2025

Lean Six Sigma on Resume for Rewarding Career Benefits

Last updated on Nov 20 2023

Categories

- Agile Management 54

- AI and Machine Learning 42

- Big Data 53

- Business Management 51

- Cloud Computing 44

- Digital Marketing 56

- Information Security 8

- IT Hardware and Networking 17

- IT Security 103

- IT Service Management 29

- Leadership and Management 1

- Microsoft Program 2

- Other 43

- Programming Language 31

- Project Management 162

- Quality Management 75

- Risk Management 8

- Workplace Skill Building 2

Trending Now

Top Career benefits of Lean Six Sigma Green Belt

ArticleLean methodology, Six Sigma methodology and Lean Six Sigma Explained

ArticleSix Sigma Black Belt Certification – Value and Career Benefits in 2024

ArticlePareto Chart in Six Sigma - Explained

ArticleQuality Management Interview Questions 2024

ArticleSix Sigma Certification Guide - A Professional's Guide

ArticleSix Sigma Yellow Belt Certification - Six Sigma for Beginners

ArticleQuality Control Explained – Six Sigma

ArticleTotal Quality Management - A Complete Guide for Beginners

ArticleQuality Assurance in Six Sigma Explained

ArticleQuality Assurance vs Quality Control

ArticleSix Sigma Certification – Everything you Need to Know About Getting Certified

ArticleLean Six Sigma on Resume for Rewarding Career Benefits

ArticleQuality Manager Interview Questions and Answers for 2025

ebookService Delivery Manager Interview Questions and Answers (With Examples)

ArticleSix Sigma Interview Questions and Answers 2024

ArticleHow to become a Quality Analyst

ArticleA Supply Chain Management Guide to Mastering Logistics End to End

ArticleSenior Quality Manager Interview Questions and Answers 2024

ArticleTop 30 Quality Analyst Interview Questions and Answers 2025

ArticleFinancial Analyst Interview Questions and Answers 2024

ArticleRisk Manager Interview Questions and Answers 2024

ArticleCompliance Manager Interview Questions and Answers 2024

ArticleOperation Manager Interview Questions and Answers

Article5 Lean Continuous Improvement Principles to Supercharge Your Operations

ArticleHow to Become a Quality Manager - Career, Job Scope and Certifications

ArticleEssential Components of a Quality Management System

ArticleSix Sigma Certifications - Reasons Why you Should Get Them

ArticleTop Qualities of a Good Manager and a Leader

ArticleLearn about Statistical Process Control (SPC) and its top applications

ArticleCost of Poor Quality - A Detailed Guide

ArticleImplementing 5S Methodology for Better Work Efficiency

ArticleWhat Is Lean Management?

ArticleBest Six Sigma Books in 2024

ArticleLeadership vs Management - The Ultimate Guide

ArticleQuality Assurance Plan - Six Steps To Quality Assurance Plan

ArticleOperational Planning Creation, Key Elements and its Benefits

ArticleA Complete Guide to Product Life Cycle Stages 2025

ArticleSix Sigma tools for DMAIC Phases

ArticleThe Lean Continuous Improvement Model: A Comprehensive Guide

ArticleDMAIC vs. DMADV: Key Differences and Choosing the Right Six Sigma Methodology

ArticleA Deep Dive into the Power of Lean Continuous Improvement Process

ArticleLean Continuous Improvement Methods for Business Excellence

ArticleIntroduction to Lean Manufacturing- Definitions, Framework, and More

ArticleUnderstanding the Key Principles of Lean Manufacturing

ArticleSecret to Unlock Organizational Excellence: Stages of Continuous Improvement

ArticleLean Continuous Improvement: A Detailed Guide to Mastering Organizational Quality

ArticleLean Waste Management: The Ultimate Guide 2023

ArticleA Deep Dive into Lean Continuous Improvement Tools

Article8 Wastes of Lean - Strategies for Identification and Elimination

ArticleThe Ultimate Guide to Lean Manufacturing

ArticleUnderstanding Lean Manufacturing's Pros and Cons

ArticleLean Waste Reduction Strategies: Boost Efficiency and Cut Costs

ArticleTop 10 Lean Manufacturing Tools for Optimal Productivity

ArticleBeyond the Basics: Benefits of Lean Continuous Improvement

ArticleWhat are Quality Standards? | A Guide to ISO Standards

Article7 Important Types of Quality Management System

ArticleA Comprehensive Guide to Quality Management Systems

ArticleISO 9001 Standard: Benefits and Certification

ArticleBenefits of QMS Certification for Your Business

ArticleStep-by-Step Implementation Guide to ISO 9001

ArticleThe Ultimate Guide to ISO 9001: Boosting Quality and Certification Success

ArticleQuality Management System – QSM Approaches and Methodologies

ArticleHow to Effectively Implement a Robust Quality Management System?

ArticleExplaining QMS Documentation Structure: Benefits and Best Practices

ArticleWho Needs ISO 9001 Certification and Why?

ArticleKey Elements of ISO 9001:2015 Quality Management System

ArticleOvercoming Common Challenges in ISO 9001 Certification: Tips and Best Practices

ArticleBest Quality Management Tools

ArticleTotal Quality Management (TQM) vs. Six Sigma

ArticleQuality Manager Salary: What Freshers & Experts Earn in 2025

ArticleCertified Scrum Product Owner: Job Roles And Responsibilities

ArticleTips for Continuous Integration Testing: Streamlining QA

Article10 Quality Management Strategies Adopted by Top Managers

Article